Metal Spinning

Our Metal Spinning Materials

Metal Spinning Process

Our process starts by examining your project specifications. We then use this along with your design to inform our spinning operations. A workpiece is then shaped with passes controlled by either a programmed machine or operated by one of our highly skilled hand spinners. We ensure even deformation with no wrinkling. We can alter machine settings and component positioning to achieve the results you need for your project.

Tooling

Tanfield has the largest standard tooling stock for metal spinning in the UK. We invest in new tools on a yearly basis to make sure our capabilities remain industry leading. The benefits are passed on to you in the form of low tooling costs.

If your project requires new tooling, Tanfield Metal Spinners will look at the most cost-effective way to service your customers’ needs.

Top things we get asked

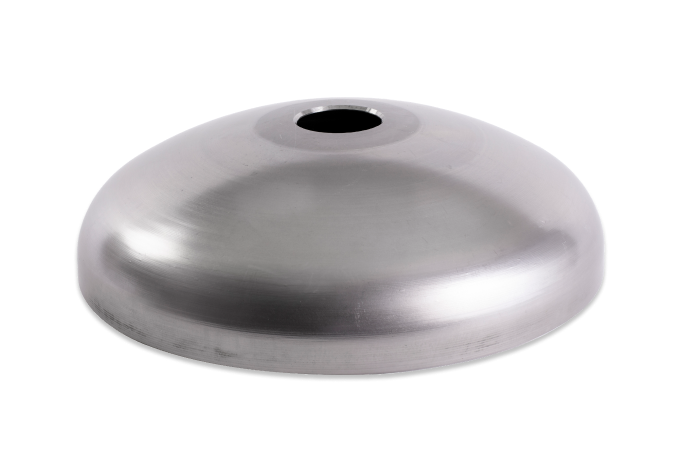

The metal spinning process is a forming technique used to shape flat metal blanks into axially symmetrical components. The material is rotated at speed while controlled pressure is applied, creating precise, seamless round parts.

Metal spinning is ideal for producing dished ends, pressure vessels, tank heads, metal cones, hemispheres, and other circular or conical components used across industrial sectors.

Yes, custom metal spinning allows components to be produced to exact specifications. Sizes, wall thicknesses, angles, and profiles can all be adjusted to suit your application.

A wide range of materials can be used, including aluminium, stainless steel, carbon steel, copper, brass, titanium, Inconel, Hastelloy alloys, and other specialist metals.

Custom metal spinning is widely used in industries such as chemical processing, food production, power generation, nuclear, oil and gas, agriculture, air movement, and manufacturing.

The process offers excellent dimensional accuracy and consistency. Skilled operators and advanced machinery ensure even material deformation with minimal waste.

Metal spinning tools include mandrels, rollers, form blocks, and bespoke tooling designed to shape components accurately while maintaining material integrity.

Not always. Many projects can use standard metal spinning tools, reducing costs. For unique designs, bespoke tooling may be produced to achieve the required shape and tolerances.

The metal spinning process is cost-effective, produces seamless components, reduces material waste, and is ideal for both small batch and large-scale production.

To begin a custom metal spinning project, provide your drawings, dimensions, material requirements, and intended application. An expert can then advise on tooling, feasibility, and the most efficient production approach.

Metal Spinning

Metal Spinning Bespoke Metal Spinning

Bespoke Metal Spinning Metal Polishing

Metal Polishing Machining

Machining Metal Pressing

Metal Pressing Metal Swaging

Metal Swaging Metal Fabrication & Welding

Metal Fabrication & Welding Precision Engineering

Precision Engineering Laser Cutting

Laser Cutting Inspection and Quality

Inspection and Quality Anodising, Electropolishing and Pickling & Passivating

Anodising, Electropolishing and Pickling & Passivating Agriculture

Agriculture Automotive

Automotive Air Movement

Air Movement Food Industry

Food Industry Marine

Marine Medical and Cryogenic

Medical and Cryogenic Playground

Playground Pressure Vessels

Pressure Vessels Renewable Energy

Renewable Energy Safety

Safety