Tailoring Standard Dished Ends to Your Requirements

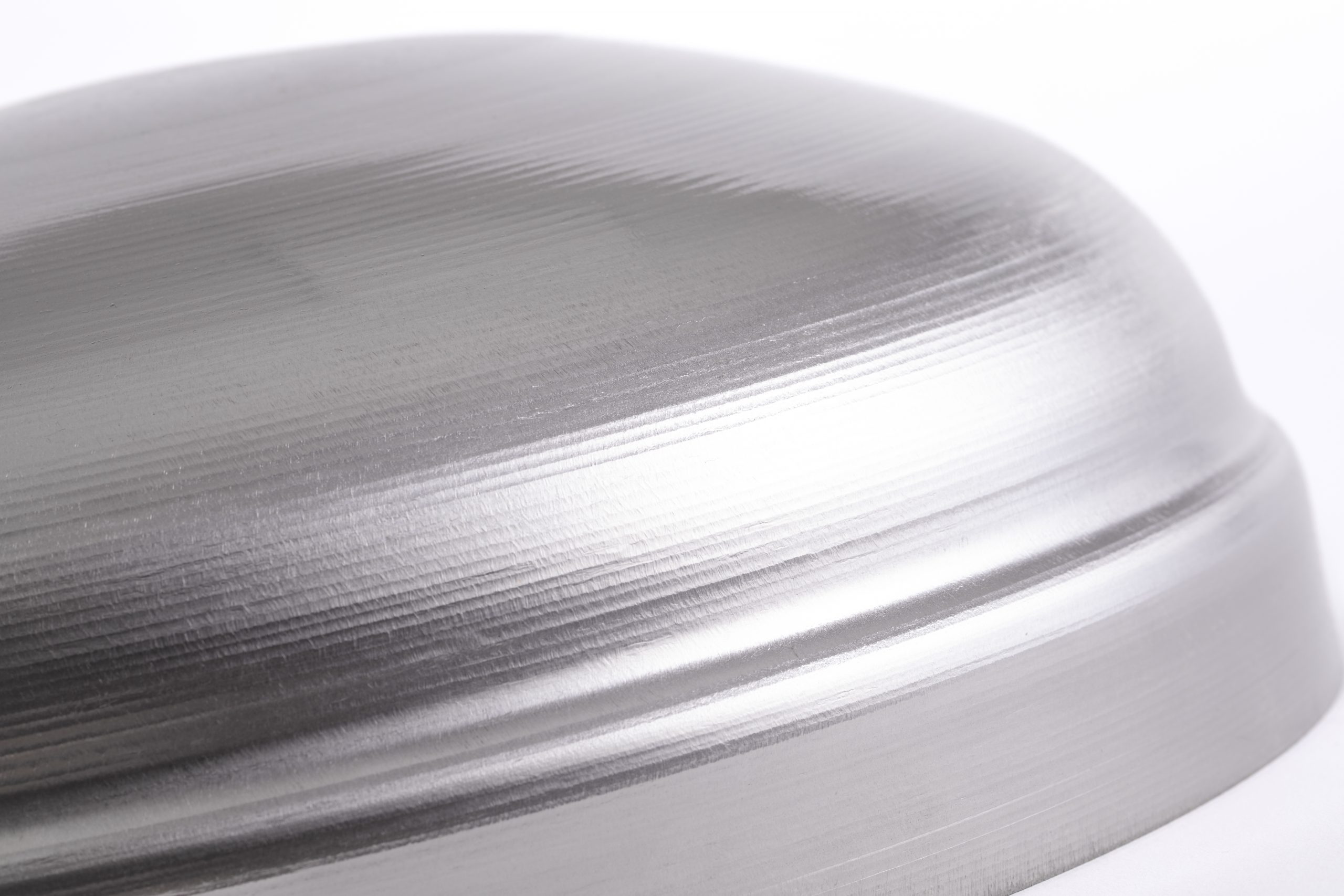

In addition to adhering to industry standards, we understand that every project has unique requirements. That’s why we offer the flexibility to tailor our standard dished ends to your specific needs. Whether you require customized dimensions, shapes, or materials, our skilled artisans and state-of-the-art equipment are ready to adapt our standard dished ends to meet your unique specifications.

As your trusted partner for precision metalwork, we are committed to delivering dished ends that not only meet your requirements but also surpass your expectations in terms of quality, performance, and aesthetics. Whether it’s for pressure vessels, architectural applications, or industrial components, we look forward to serving your unique needs with our top-quality, ISO-accredited dished ends.

Adhering to Standards with ISO Accreditation

At Tanfield Metal Spinners, we take immense pride in our commitment to quality and precision. Our dished ends are not just any dished ends; they are crafted to meet and exceed industry standards. We hold ISO accreditation, a testament to our dedication to delivering excellence in every product we manufacture.

With ISO accreditation, our customers can be confident that our dished ends adhere to internationally recognized quality management standards. This accreditation ensures that our processes are consistently monitored and improved, leading to products that meet the highest industry benchmarks.

Metal Spinning

Metal Spinning Bespoke Metal Spinning

Bespoke Metal Spinning Metal Polishing

Metal Polishing Machining

Machining Metal Pressing

Metal Pressing Metal Swaging

Metal Swaging Metal Fabrication & Welding

Metal Fabrication & Welding Precision Engineering

Precision Engineering Laser Cutting

Laser Cutting Inspection and Quality

Inspection and Quality Anodising, Electropolishing and Pickling & Passivating

Anodising, Electropolishing and Pickling & Passivating Agriculture

Agriculture Air Movement

Air Movement Food Industry

Food Industry Playground

Playground Pressure Vessels

Pressure Vessels Renewable Energy

Renewable Energy Safety

Safety