Wall Thickness, Tolerances, and Surface Finish in Metal Spinning Explained for Non-Engineers

In the world of metal fabrication and manufacturing, selecting the right metal forming process can make or break a project’s success. Design engineers often face the challenge of balancing cost, precision, production volume, and material properties when deciding between techniques like metal spinning, deep drawing, and presswork. These sheet metal forming methods each have unique strengths but understanding when to opt for one over the others is crucial for optimizing efficiency and quality in custom metal parts production.

This guide delves into the intricacies of this metal forming processes, highlighting key factors such as tooling costs, material versatility, and application suitability. Whether you’re working on aerospace components, automotive parts, or industrial equipment, we’ll explore why metal spinning, particularly CNC metal spinning, often emerges as the superior choice for many scenarios. Drawing from industry expertise, including insights from leading providers like Tanfield Metal Spinners in the UK, this article aims to equip you with practical knowledge to make informed decisions in precision metal spinning and beyond.

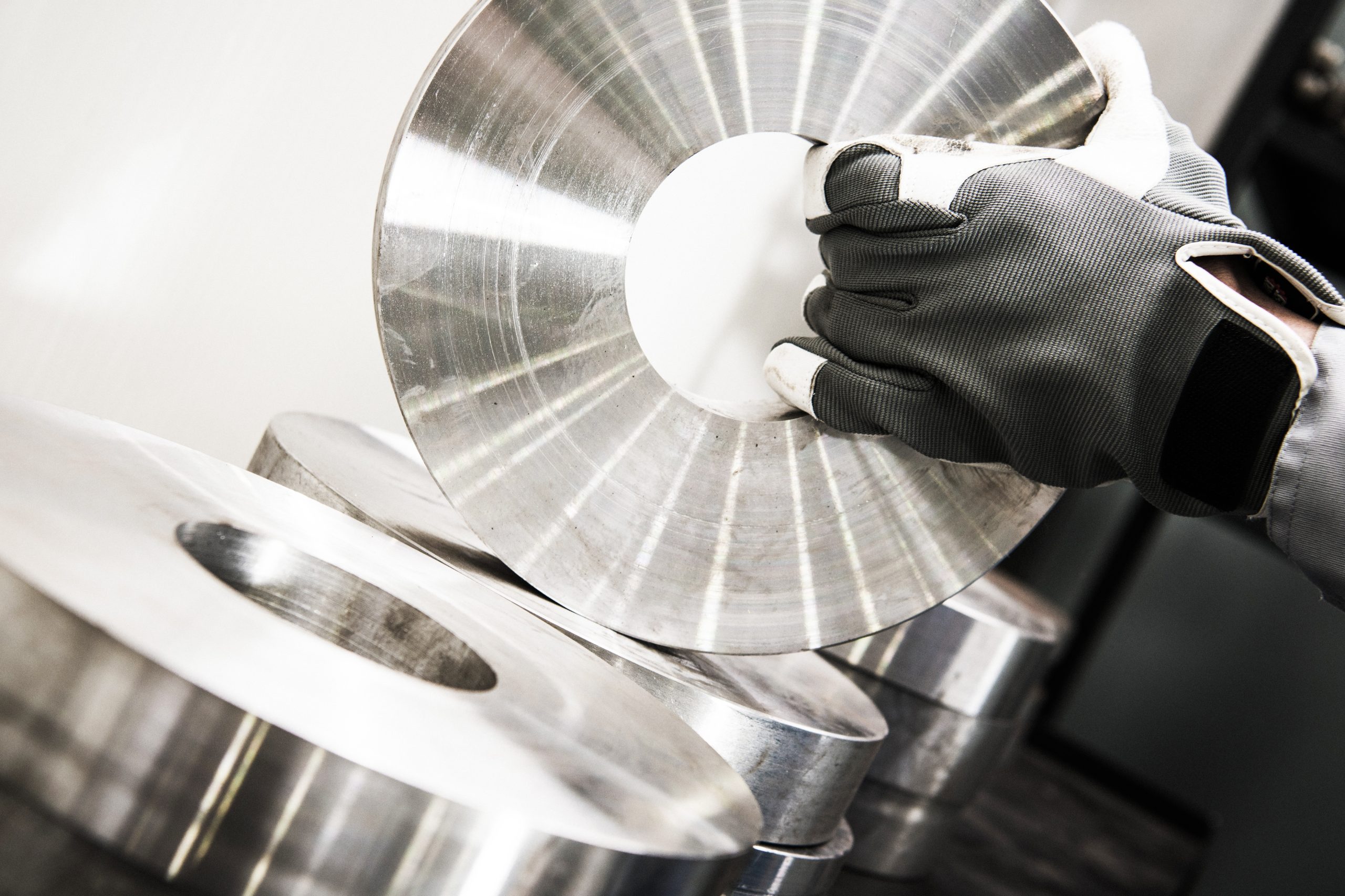

Metal spinning, also known as spin forming or metal turning, is a sheet metal forming technique that involves rotating a metal disc or tube at high speeds while applying pressure with a tool to shape it into a symmetrical, hollow part. This process is ideal for creating conical, hemispherical, or cylindrical shapes, such as pressure vessels, metal cones, flat flanged ends, dished plates and dished ends.

One of the standout features of metal spinning is its flexibility. Unlike more rigid methods, it allows for rapid prototyping and adjustments without extensive retooling. CNC metal spinning takes this a step further by incorporating computer numerical control for enhanced precision and repeatability, making it perfect for high-tolerance applications in sectors like renewable energy, agriculture, and food processing.

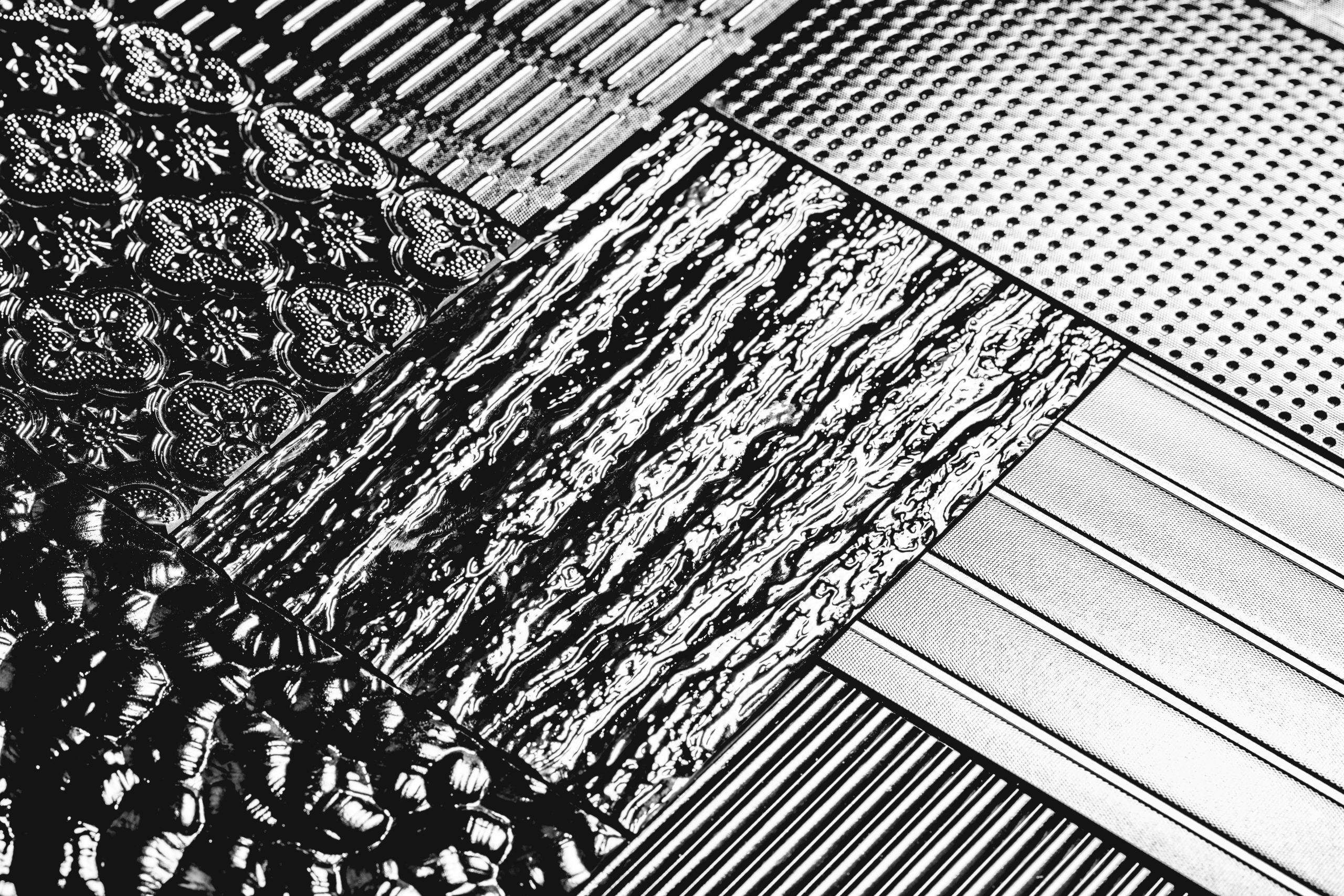

Key advantages include low tooling costs, often significantly cheaper than those for deep drawing or presswork, making it economical for both low-volume and high-volume production runs. Materials like stainless steel, aluminium, copper, and even exotic alloys such as titanium or Hastelloy can be spun, with thicknesses up to 14mm handled efficiently. Providers like Tanfield Metal Spinners, with their ISO9001-accredited facilities, emphasize how metal spinning reduces material waste and supports bespoke designs, often delivering quotes within 24 hours and lead times of 3-4 weeks, lead times can also be discussed with the customer or call off orders can be arranged.

In practice, metal spinning excels in creating seamless parts with excellent structural integrity, avoiding welds that could weaken the final product. This makes it a go-to for safety-critical components in playground equipment or air movement systems.

Deep drawing is a metal forming process where a flat sheet of metal is drawn into a die using a punch to create cup-shaped or box-like components. It’s commonly used for producing items like beverage cans, automotive fuel tanks, and kitchen sinks. The process relies on the metal’s ductility to stretch without tearing, often requiring multiple draws for deeper shapes.

This technique shines in high-volume manufacturing due to its ability to produce consistent parts at scale. Tooling for deep drawing, however, can be expensive upfront, involving custom dies and punches that must withstand repeated use. It’s best suited for materials like mild steel, aluminium, and brass, with thicknesses typically ranging from 0.9mm to 3mm.

While deep drawing offers excellent surface finishes and tight tolerances, it has limitations.

Complex geometries or asymmetrical designs can lead to defects like wrinkling or thinning, necessitating lubricants or annealing steps. For design engineers, deep drawing is preferable when production runs exceed thousands of units, as the amortized tooling costs become negligible. However, for prototypes or small batches, the initial investment can be prohibitive compared to more flexible options like metal spinning.

Presswork, or metal pressing, encompasses a broad range of operations using mechanical or hydraulic presses to shape, cut, or form metal sheets. This includes stamping, punching, bending, and blanking, making it a staple in custom metal fabrication for parts like brackets, enclosures, and automotive panels.

Hydraulic presses, such as those with 350-ton capacity used by specialists like Tanfield Metal Spinners, can handle large beds (up to 1220 x 1500mm) and depths of 650mm, accommodating thicknesses from 0.9mm to 10mm. Presswork is highly efficient for repetitive tasks and integrates well with other processes like welding or machining.

Advantages include speed and cost-effectiveness for medium to high-volume runs, with progressive dies enabling multiple operations in one cycle. However, tooling costs are high, and changes to designs often require new dies, limiting flexibility. Materials must be carefully selected to avoid cracking, and the process generates more waste than spinning due to scrap from punching.

Presswork is ideal for flat or mildly contoured parts but struggles with deep, hollow shapes where deep drawing or metal spinning might be better.

To decide when to choose metal spinning over deep drawing or presswork, consider these critical aspects of metal forming processes:

For low-volume custom metal parts, metal spinning’s affordability and quick setup win out.

If your design requires seamless, rotational symmetry, precision metal spinning is often the optimal choice.

Metal spinning’s ability to work with diverse materials, including corrosion-resistant options like Duplex or Nirosta, gives it an edge in demanding environments.

In fast-paced industries, the responsiveness of metal spinning providers like Tanfield, offering free design advice and in-house capabilities from laser cutting to anodising, streamlines the process.

Overall, lifecycle costs favour metal spinning for varied applications.

Opt for metal spinning when flexibility and cost savings are paramount. For instance, in renewable energy, spinning creates efficient wind turbine components with minimal waste. A case study from Tanfield Metal Spinners involved producing custom conical parts for air movement systems, where deep drawing would have required costly multi-draw tooling, but spinning delivered prototypes in days.

In the food industry, hygienic, seamless vessels spun from stainless steel outperform pressed alternatives prone to crevices. Design engineers in aerospace appreciate spinning’s precision for lightweight, high-strength parts like engine housings, avoiding the rigidity of presswork.

Conversely, choose deep drawing for mass-produced cans or presswork for stamped brackets.

But if your project involves low to medium volumes, complex symmetries, or rapid iterations, metal spinning, especially with integrated services like metal polishing and welding, provides unmatched value.

As a design engineer, mastering the nuances of metal forming processes like metal spinning, deep drawing, and presswork ensures projects meet deadlines, budgets, and performance standards. While deep drawing and presswork dominate high-volume, uniform production, metal spinning’s versatility, low costs, and precision make it the practical choice for many modern applications.

For expert guidance, consider partnering with UK-based specialists like Tanfield Metal Spinners, who offer end-to-end solutions from bespoke metal spinning to precision engineering. By evaluating your specific needs, volume, geometry, and materials, you can select the right process to drive innovation in sheet metal fabrication.