When to Choose Metal Spinning Over Deep Drawing or Presswork: A Practical Guide for Design Engineers

If you’ve ever wondered how a flat sheet of metal turns into a perfectly shaped cone, bowl, or pressure vessel without any seams, the answer often lies in metal spinning. This age-old yet highly effective metal forming process creates strong, lightweight, and symmetrical parts used in everything from kitchenware and lighting fixtures to aerospace components and industrial equipment.

For people without an engineering background, perhaps product designers, buyers, project managers, or business owners, this blog breaks down three key aspects of metal spinning: wall thickness, tolerances, and surface finish. We’ll explain what they mean in simple terms, why they matter, how metal spinning handles them compared to other methods, and what to expect when working with a specialist like Tanfield Metal Spinners in the UK.

Understanding these basics helps you communicate better with manufacturers, avoid surprises in costs or lead times, and get the best results for your custom metal parts.

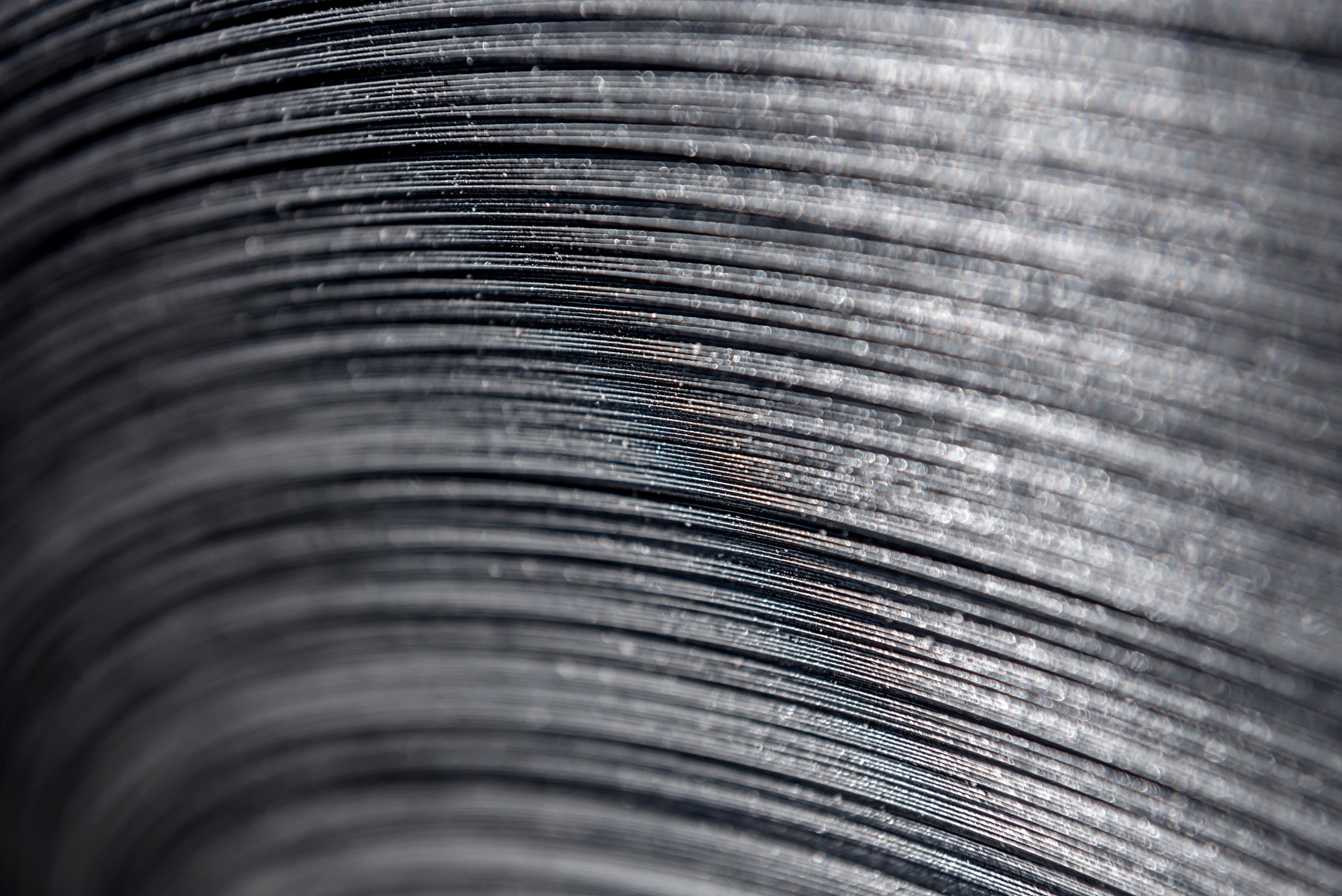

Metal spinning (also called spin forming or spin turning) works like pottery on a wheel, but with metal. A flat disc (called a blank) spins rapidly on a lathe while skilled operators or CNC machines press tools against it, shaping it over a mandrel (a solid form that defines the inside shape). The result is a seamless, hollow part with excellent strength because the metal’s grain structure gets realigned during the process.

Tanfield Metal Spinners, a leading UK provider, handles everything from prototypes to production runs using CNC and automated spinning lathes. They work with materials like stainless steel, aluminium, copper, titanium, and more exotic alloys, spinning up to 14mm thick ( depending on what material is used ) and diameters up to 2.4 metres (with partners for larger sizes). This versatility makes metal spinning ideal for bespoke projects in industries like renewable energy, food processing, and agriculture.

Wall thickness refers to how thick (or thin) the final part’s material is after spinning.

In many metal forming processes, the starting thickness stays roughly the same. But in metal spinning, the metal stretches and flows as it’s forced over the mandrel. This causes thinning, especially in deeper or more dramatic shapes like cylinders or hemispheres.

Why does this matter? Thinner walls save weight and material cost but can reduce strength. Thicker walls provide durability for pressure vessels or structural parts. Good design balances these, gentle angles and larger radii reduce excessive thinning, making production easier and more consistent.

In practice, if uniform thickness is critical, specify it clearly. Secondary machining after spinning can refine thickness where needed, though this adds cost.

Tolerances are the allowed variation in dimensions, how much the actual part can differ from your drawing without causing issues.

Metal spinning isn’t as precise as CNC machining or milling because it’s a forming process involving metal flow under pressure. However, modern CNC metal spinning achieves impressive accuracy, especially for axisymmetric (round) shapes.

Factors affecting tolerances:

Tighter tolerances increase time, care, and cost, sometimes requiring extra tooling or post-machining. Over-specifying can drive up prices unnecessarily. Tanfield offers free design advice to help optimise tolerances for manufacturability, ensuring parts meet your needs without excess expense.

For non-critical applications like decorative lighting or ventilation components, standard tolerances work fine. For precision needs like aerospace fittings, discuss achievable specs upfront.

Surface finish describes how smooth or textured the part’s exterior looks and feels, measured in roughness (Ra value) or visually.

Freshly spun parts have a characteristic tool-marked finish from the spinning rollers. It’s functional but not always polished.

Tanfield excels here, their in-house polishing and finishing services turn industrial parts into high-end products. For applications like playground equipment or air movement systems, a smooth finish prevents dirt buildup and improves safety.

Imagine designing a stainless steel cone for a ventilation system:

Tanfield would advise on blank thickness, suggest draft angles to minimise thinning, quote polishing if needed and advise on what tolerances we can work towards, all with ISO9001 quality assurance and full material traceability.

Compared to deep drawing or presswork, metal spinning often delivers better natural strength and fewer seams, though it may require more attention to thinning and tolerances for complex shapes.

Metal spinning combines craftsmanship with modern CNC precision to create durable, cost-effective parts. By understanding wall thickness, tolerances, and surface finish, you can make smarter choices and get outstanding results.