Top 5 Benefits of Using Bespoke Metal Spinning for Your Product Development

Product development requires precision, flexibility, and efficiency in today’s fast-paced manufacturing landscape. Bespoke metal spinning offers an exceptional solution for manufacturers seeking customised, high-quality metal components. Metal spinning provides a cost-effective, scalable, and versatile approach to shaping metal, making it an ideal choice for industries ranging from aerospace to lighting and beyond.

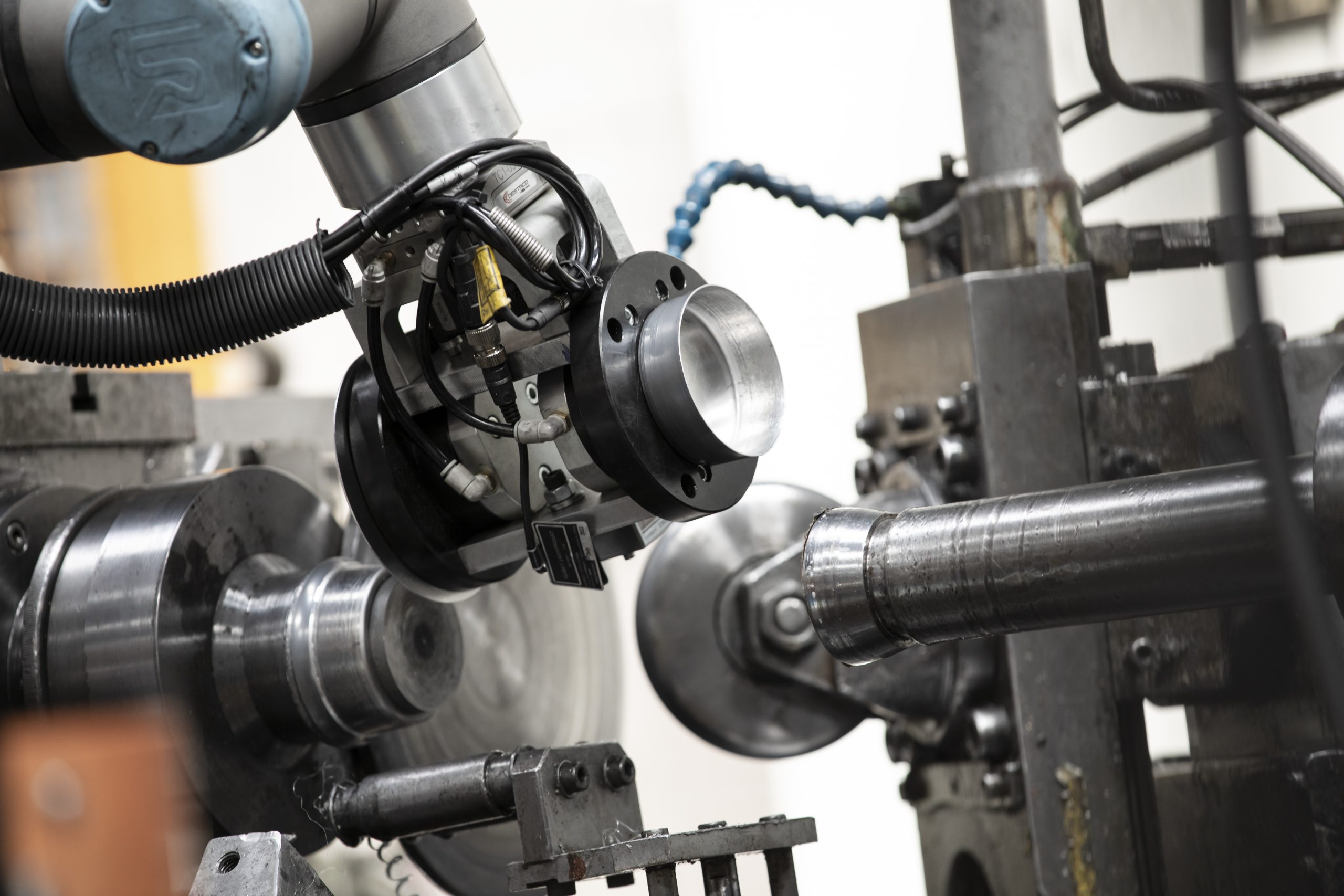

At Tanfield Metal Spinners, we specialise in providing tailored metal spinning solutions that meet our customers’ exact specifications. With an extensive tooling range and fully automated processes, we ensure high-quality, time-efficient, and cost-effective results. Here, we explore the top five benefits of using bespoke metal spinning for your product development and why it should be your go-to manufacturing solution.

Precision and Design Flexibility

One of the most significant advantages of bespoke metal spinning is the ability to create highly precise and intricate designs. Unlike stamping or casting, which may require costly moulds or tooling, metal spinning allows for the cost-effective production of custom shapes with tight tolerances and seamless finishes.

Manufacturers can achieve superior accuracy using computer-controlled CNC metal spinning, ensuring that every component meets exact specifications. This level of precision is particularly beneficial for industries requiring intricate detailing, such as medical equipment, defence applications, and high-performance automotive parts. The process also allows for quick design modifications, making it easy to refine prototypes and adapt to evolving project requirements.

Cost-Effective Production for Custom Parts

Custom manufacturing often comes with significant costs; however, bespoke metal spinning offers an economical solution that reduces material waste and minimises tooling expenses.

Since metal spinning relies on forming techniques rather than cutting away excess material, it maximises material usage, making it an environmentally friendly and cost-efficient choice. Moreover, the process requires less complex and expensive tooling than deep drawing or stamping, making it ideal for low-volume and high-volume production runs. This cost advantage is particularly valuable for businesses developing specialist prototypes or custom components where affordability and quality must go hand in hand.

Strength and Durability of Components

Bespoke metal spinning enhances the mechanical properties of metal components by carefully aligning the grain structure during the forming process. This process results in stronger, more durable parts that outperform components made through other fabrication methods.

The work-hardening effect of metal spinning ensures that spun parts have superior tensile strength, allowing them to withstand extreme conditions, such as high temperatures, pressure, and corrosive environments. This hardening effect makes metal spinning a preferred choice for industries where material integrity is paramount, such as aerospace, energy, and food processing equipment.

By selecting bespoke metal spinning, manufacturers can ensure that their components meet stringent performance and longevity requirements without additional reinforcement or complex secondary processes.

Rapid Prototyping and Speed to Market

The ability to move from concept to production quickly is crucial in fast-moving, competitive industries. Bespoke metal spinning enables rapid prototyping, allowing manufacturers to test and refine designs rapidly.

Casting or forging requires extensive setup times, whereas metal spinning can quickly produce functional prototypes without lengthy lead times. This agility enables businesses to accelerate their product development cycles, reducing time to market while maintaining high standards of quality and precision.

At Tanfield Metal Spinners, our advanced CNC machinery ensures fast turnaround times without compromising on accuracy, making it easier for manufacturers to keep up with demand and respond to market shifts efficiently.

Sustainability and Waste Reduction

As industries continue to prioritise sustainability and environmental responsibility, metal spinning presents a green alternative to conventional metal forming methods. The process produces minimal waste, as it shapes metal rather than cutting away excess material. This optimised material usage not only reduces costs but also minimises the environmental impact of manufacturing.

Additionally, metal spinning is compatible with a wide range of recyclable metals, including aluminium, stainless steel, and copper, making it an eco-conscious choice for companies looking to enhance their sustainability credentials. By choosing bespoke metal spinning, manufacturers can contribute to a circular economy while maintaining product integrity and performance.

Unlock the Full Potential of Bespoke Metal Spinning

Bespoke metal spinning offers a versatile, cost-effective, and environmentally friendly solution for manufacturers seeking high-quality metal components. With unmatched precision, enhanced durability, and rapid production capabilities, it is an ideal choice for industries that require custom metal parts without the high costs of traditional fabrication methods.

At Tanfield Metal Spinners, we pride ourselves on delivering flexible and responsive metal spinning services, ensuring we craft every component to meet the unique demands of your project. Whether you require a one-off prototype or a large-scale production run, our expertise and cutting-edge technology provide the perfect foundation for success.

Looking to incorporate bespoke metal spinning into your product development? Contact Tanfield Metal Spinners today and discover how our advanced manufacturing solutions can elevate your next project.

Talk to an ExpertLooking to incorporate bespoke metal spinning into your product development?

Contact Tanfield Metal Spinners today and discover how our advanced manufacturing solutions can elevate your next project.

Talk to an Expert

Metal Spinning

Metal Spinning Bespoke Metal Spinning

Bespoke Metal Spinning Metal Polishing

Metal Polishing Machining

Machining Metal Pressing

Metal Pressing Metal Swaging

Metal Swaging Metal Fabrication & Welding

Metal Fabrication & Welding Precision Engineering

Precision Engineering Laser Cutting

Laser Cutting Inspection and Quality

Inspection and Quality Anodising, Electropolishing and Pickling & Passivating

Anodising, Electropolishing and Pickling & Passivating Agriculture

Agriculture Automotive

Automotive Air Movement

Air Movement Food Industry

Food Industry Marine

Marine Medical and Cryogenic

Medical and Cryogenic Playground

Playground Pressure Vessels

Pressure Vessels Renewable Energy

Renewable Energy Safety

Safety