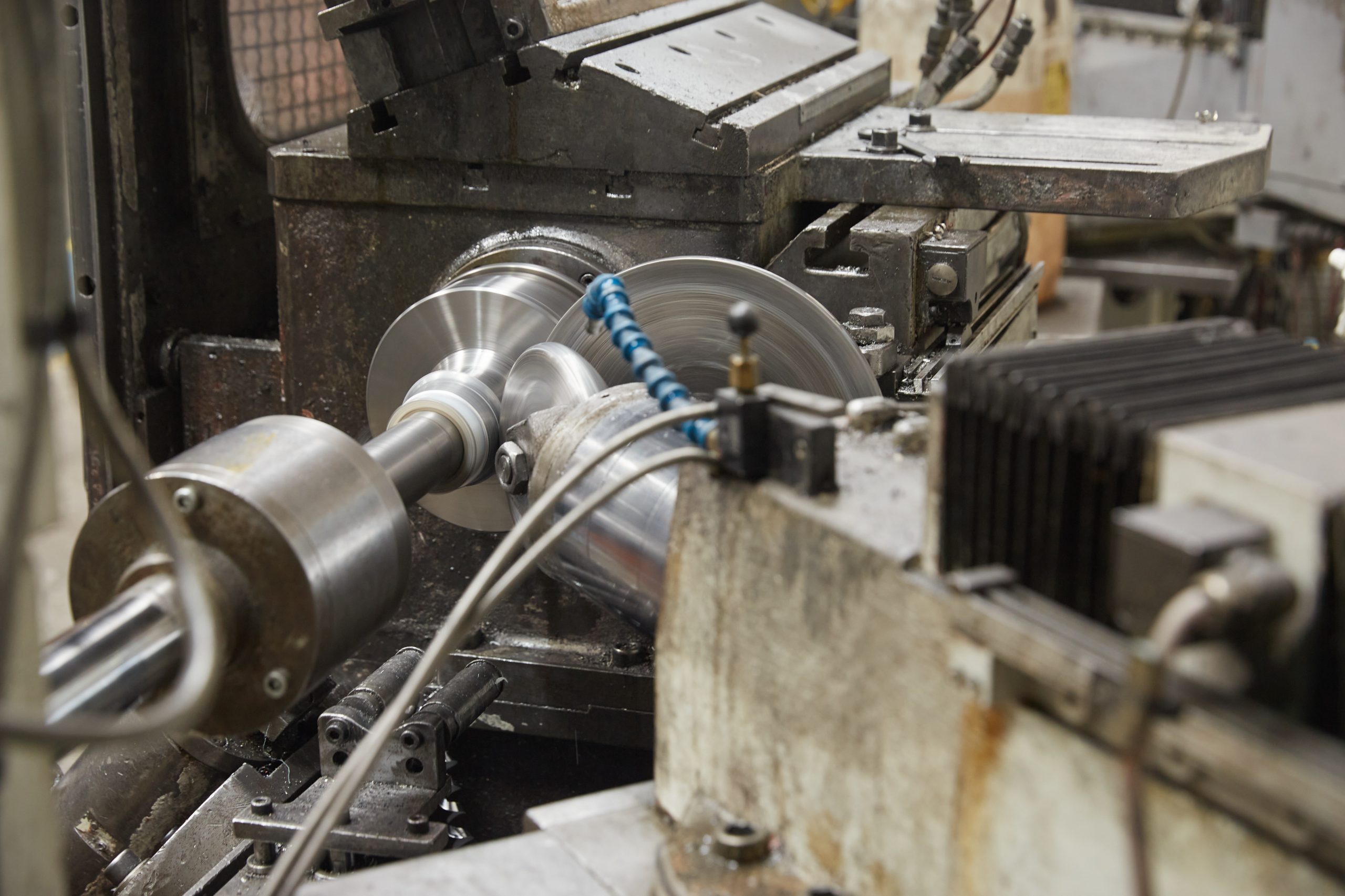

Metal Engineering Specialists, Spinning and Forming The Widest Range of Metals

Tanfield Metal Spinners are a fully automated specialist metal former capable of spinning and forming the widest range of metals and shapes used by today’s leading manufacturers.

The Top Things We Get Asked

Metal spinning, also known as spin forming, is a cost-effective process used to form conical, hemispherical, and cylindrical shapes. A starting blank (flat disk) is spun over a tool in a series of sweeps by a forming roller. The metal is progressively shaped onto the tooling to produce the desired shape, and provide you with the ideal finished part.

In general, metal spinning offers flexibility with low tooling costs and is widely used for either low or high-volume production. Depending on the application, spinning can offer major benefits which often makes it an ideal choice.

Tanfield Metal Spinners will quote for work up to a circumference of 2.4 meters and 10mm thick. We also partner with an international spinning company for anything above Tanfield Metal Spinners’ current capabilities.

Our technical engineering department will supply a drawing upon your request for a quote, at no additional cost. This drawing can be signed off before placing an order.

All parts manufactured by Tanfield Metal Spinners will have full traceability. All materials that require certification will be automatically sent to our customers upon completion of the order.

The following materials can all be spun. If your project requires a different metal, we can work with many more specialist materials, however these will typically require heat (annealing) to meet your specifications.

Aluminium

Brass

Carbon Steel

Copper

Corten

Duplex

Hastelloy Alloys

Inconel

Mu-metal

Nimonic

Nirosta

Silver

Stainless Steel

Titanium

Zintec

Tanfield Metal Spinners prides itself on maintaining a 3–4-week lead time where possible. If tooling is required this can extend the lead times.

Tanfield Metal Spinners’ standard tooling stock is the largest in the country and we invest in it on a yearly basis.

If your project requires new tooling, Tanfield Metal Spinners will look at the most cost-effective way to service your customers’ needs.

Delivery is always a next day service; this can be upgraded to “before 12 noon UTC” at an extra cost.

Meet the Tanfield Metal Spinners Team